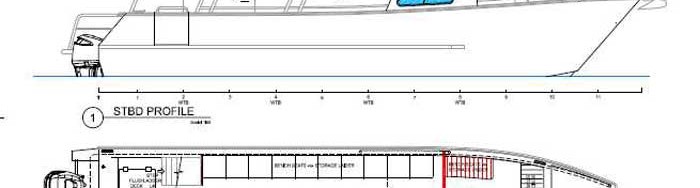

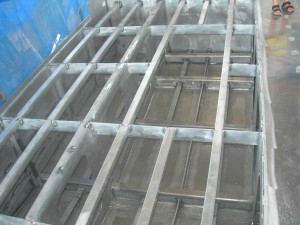

This 11.80 meter aluminum ferry which is being built to Australian government survey NSCV 1D now has the hulls fully plated and 60% of the hull internal welding finished. The first survey inspection was passed two weeks ago and construction is on schedule.

Hull plating has proceeded without a hitch and all parts fitted exactly.

We are currently stopped for the annual Songkran festival [Thai New Year] and work will restart on the 20th April 2015.

Ferry for Pumpkin Island, Queensland – Week 4

Frame set-up was completed early in Week 3 and we now have all the tunnel and inner side plate fitted and tacked. Bottom plate outside up to the chine has also been fitted and tacked. We now await the first visit from the Australian surveyor and. assuming all is ok, will start fully welding the hulls inside and the main deck.

New Construction – Ferry for Pumpkin Island, Australia

Last week we started construction of an 11.80M ferry to be shipped to Yeppoon in Queensland, Australia. This vessel will be powered by twin Yamaha 300HP outboards and is being built to survey. A special feature will be the forward boarding ramp and the boat will have passenger access to and seating on the upper deck.

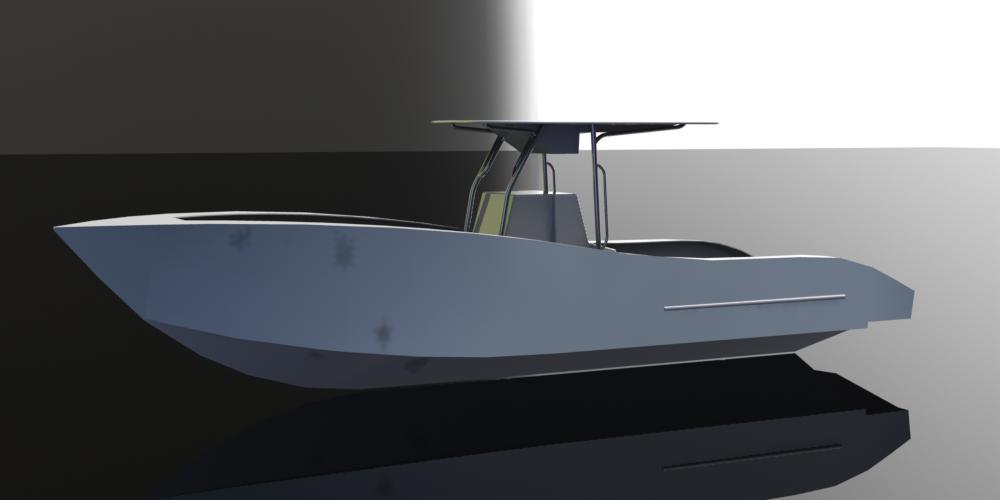

30′ monohull construction

New 30′ monohull construction is now complete and this boat is for sale. Center console has been installed, however, a cuddy or full cabin can be fitted if required. Power requirement can be single 250 – 350HP outboard or a twin installation up to 600HP.

To enquire about this boat contact info[at]boatsbycoastal[dot]com.

Motorized aluminum barge/work platform for Marina or general use

Next project about to get underway is a Motorized Aluminum Barge/Work Platform specifically designed for use in a mining company tailings dam.

The vessel will be fitted with a manual crane and be powered by a Perkins M92B engine with ZF 3.01:1 marine gear. Propeller size is calculated at 23″ x 23.5″ x 4B x 0.70(KCA), with Prop efficiency: 41.8%.

Designed mainly as a working platform to handle a maximum loading of 600kg it will also have excellent pull/push ability.

This very capable vessel with a top speed of 7 knots will be ideal for use in a Marina providing a stable working platform for general maintenance, boat engine removals etc.

Two fold-up 1 meter wide working platforms are fitted, one forward and the other extending 4 meters along the starboard side. These are designed to enable easy access when working on floating pipelines within the tailings dam.

|  |

|  |

|  |

Stormy days but signs of life in Boat Building

The recession was looming but builders were being advised to follow the auto industry by consolidating brands, streamlining production and improving or refining proven models. Then the economy went into reverse and the leisure boat market evaporated.

Many big name builders were left ‘high and dry’ with their now efficient mass production lines. However, there were still signs of life in some smaller custom and semi-custom boat yards which, by being smaller, normally did not run with a high level of debt. These smaller shops also have the versatility, tools and skills to be able to build to a clients’ ambitions.

The quick thinking and versatility that helps these shops survive in hard times also renders them as development grounds for new techniques and products. In fact, most of the successfully mass produced elements of boat builds evolved out of these smaller businesses building custom boats for both the commercial and recreational markets.

These independent boat yards can be a little single-minded but they are where interesting designers and clients go to try new ideas long before tooling or production runs are thought about.

It is great that this industry still has space for independent minds and skills to enable it to keep plugging along even when times are hard. Builders who can take a design and refine or improve it to suit a customer who is willing to pay a fair price are the cornerstone of the boat building industry.

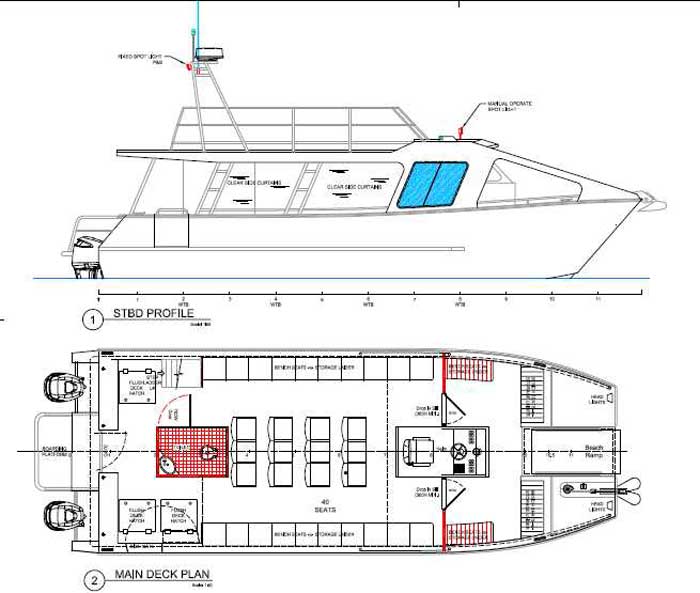

30′ Aluminum Passenger/Cargo Vessel

The brief for this project was to supply a vessel suitable for passenger use but which could also carry up to two tons of cargo when necessary and with seating removed. Again we looked to Specmar Design for a suitable plan and CNC kitset.

Power needed to be big enough to push the boat along at reasonable speed when fully loaded and to enable high speed when running as a passenger service. Selected engine was Yanmar 6LPAM-STZP2 which has a rating of 315 HP @ 3,800 rpm. Drive fitted is the Mercruiser Bravo II-X sterndrive unit.

The cabin is built using epoxy/foam sandwich in order to keep boat weight down and for aesthetic reasons ie. nice rounded corners and better styling than can be attained easily using aluminum.

|  |

|  |

|  |

|  |

|  |

Aluminum Landing Craft

This vessel was constructed for an up-market Phuket resort. Access to the resort is only by sea and the owner wanted an adaptable, fast, safe and reliable boat. The landing craft is used for passenger and stores transportation, day picnic excursions and dive trips.

This design is from Specmar and the vessel is powered with a 240 HP Yanmar LHAM diesel plus Mercruiser Bravo II-X sterndrive unit.

Top speed during sea trials was 28 knots with comfortable cruising in medium sea conditions at 22 knots.

|  |

|  |

|  |

|  |

|  |

|  |

|